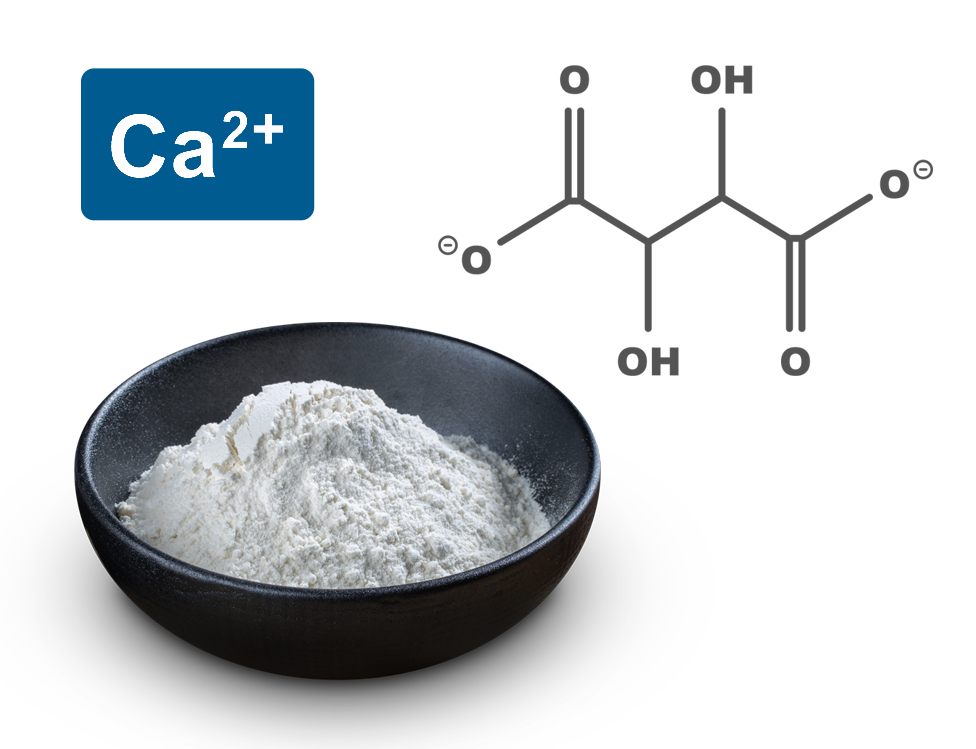

Solid and liquid wine lees are natural subproducts derived from the vinification process. We feed them to our distillation, tartrate-concentration, and anaerobic digestion plants to obtain alcohol, calcium tartrate, and biogas. Our wine lees production process significantly contributes to achieving a sustainable circular economy.